CSP Strength & Yarn Count Software

CSP Strength & Yarn Count Software

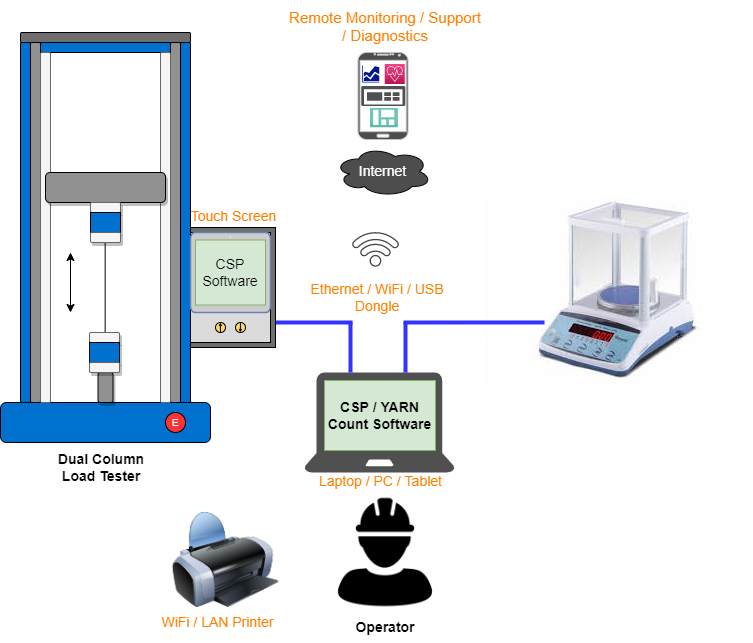

Next generation IoT based software to test the CSP (Count Strength Product) of Lea/Skein/Yarn of wool, cotton etc.

- Supports connectivity with various types of low/ medium/high precision weight scales connected via RS232, 485 or other interfaces

- Supports Direct as well as Indirect system of yarn counts such as Tex, DeciTex, Denier, English Count, Worsted, Metric, French etc.

- Supports Count, Count Strength Product (CSP) as well as GSM modes

- Create/ Edit tests, run multiple tests, save or discard tests in reports, view old reports, print customizable PDF reports

- loT enabled with remote technical support and remote software updates

Feature Details

Create New Test Program

1. Create a new test program

2. Open / edit an existing test program

3. Configurable units for load and displacement

• Load: ‘kg’, ‘lbs’, ‘N’, ‘daN’, …

• Displacement: ‘inch’, ‘mm’, …

4. Support three modes of operation

• Until Load

• Until Displacement

• Until Peak Load with Sensitivity

5. Supports holding the sample at peak load for defined time

Support three types of speed:

• Approach , Test and Return Speed

6. Enable / disable auto return to home position

7. Support margin lines (1st and 2nd margin)

8. Display displacement for 5 pre-defined load values

Create New Test Program

1. Detect configured number of highest peaks

2. Comes pre-loaded with a number of tests

3. Flexibility to create any new test based on (or otherwise) industry standards like ASTM, ISO and others

Calibration

1. Simple and guided calibration for:

• Load cell

• Displacement

• Speed

2. Calibration screen is password protected with administrator access only (different from operator password)

Run Test Program

1. Manual as well as software inching

2. Automatic home position based on sample height

3. Run multiple tests in batch mode with combined report

4. Load vs. Displacement graph with values on mouse hover

5. Displays current as well as peak load and displacements

6. Support tare of load as well as current displacement

7. Save or discard the current test run

8. View report as PDF document

Program List

2. Ability to search any program based on keywords, date of creation, customer, etc.

3. Click to open and edit any exiting test program

4. Click to directly run the test program

5. Delete any existing test program

6. Import / Export program list to CSV/XLS formats

Test Report History

1. Shows list of reports for all the saved test runs

2. Click to open any exiting test report

3. Download any report (as PDF) as well as take direct prints

4. Report shows comprehensive information about respective test run

• Test program summary

• Peak/ mean/ median values, Standard Deviation (SD), coefficient of variances, +more

• Load vs. Displacement graph for selected (or all) test runs

5. Click on the graph to show exact load / displacement values

6. Ability to select one/more/all test runs (in a consolidated report) and generate report for only the selected runs

Factory Settings

1. Supports a rich set of configuration options to:

• Enable /disable a number of features

• Set safety limits for certain parameters e.g., minimum/maximum speed, per channel load cell capacity, per channel load cell minimum discord value, per channel over load value etc.

2. Factory settings screen is password protected with administrator access only (different from operator password)

Remote Tech. Support

1. Software can be easily upgraded over remote session

2. Any aspect of the software platform can be easily debugged, supported, maintained as well as demoed over remote sessions (including PLC updates). It is handy in a number of scenarios e.g.,

• If customer needs any help in creation/edit of a test program

• If customer needs re-calibration of load cell or any other aspect

• If customer is performing some test incorrectly

Other Features

1. Software and thus the machine can be accessed by the operator via PC/ Laptop/ Tablet or inbuilt capacitive touch screen

2. Software comes with a cloud service to track certain aspects of the machines (fitted with the software)

• Location of the machines on map

• Usage of the machines

• Error conditions

• Key metrics which are meaningful for the vendor

3. Software supports top as well as bottom limit switches for machine protection against unfortunate events

e.g., machine movable heads pressing against each other during incorrect manual inching

Other Features

2. Vendor logo can be easily updated

3. Detailed machine diagnostics

Key Features of Our Software(s)

Next Generation, Intuitive, Intelligent and Safer Testing Software

Mobile App

Custom mobile app and cloud dashboard for device monitoring, statistics, alerts and notifcations.

IoT / Industry 4.0 Enabled

Internet-Of-Tings (IoT) capability enables seamless remote technical support, diagnostics and data analytics. Enables supervisors & operators to always remain connected with the machine from within or outside the factory

Intelligent Insights

Collects detailed machine and test statistics to predict and report anomalies b. IoT cloud dashboard enables detailed product insight such as test runs per day, operator effciency, days to next service cycle, error statistics, calibration reminders, software update notifcations etc

Simple and Intuitive

Operator dashboard with intuitive, easy-to-understand controls for simple workfow navigation . Easy to create new tests or edit existing ones . Save and print reports (PDF and other formats)

Future Proof Software

Remote software update (for adding new features or fxing bugs) always keeps the software up-to-date and safe . Supports remote addition of new test methods. Our team is always busy adding new features to keep your machine always ahead of the competition

Data Analytics

IOT cloud dashboard enables detailed product insights such as test runs per day, operator efficiency, days to next service cycle, error statistics, calibration reminders, software update notifications etc.

Customizable and White Labelled

Product is fully customizable. Product is white labelled and shall carry your branding

Others

Factory settings to enable/disable features (e.g., seam slippage) .Touch screen support of desired sizes . Sensors and Camera connectivity (optional)

Adding intelligence to your machines.

As technology partners, we help our customers revamp their existing machines with cutting edge technology and convert them into best-in-class IoT enabled industrial machines. Our next generation software solutions can help you surpass competition at a global scale.